Local Distillery Produces Hand Sanitizer during Coronavirus Pandemic

by Molly Kelly, Enology Extension Educator

Due to shortages brought on by the coronavirus outbreak, hand sanitizers are being produced in hundreds of distilleries around the country, including Nomad Distilling Company (formerly Mountain Top Distillery) in Williamsport, PA. Owners Sarah and Frank Kudlack purchased Bastress Winery in March 2018. These Philadelphia natives have always been small business owners and investors. When her parents retired to the area in 2010

The Kudlack family (Photo by Caterina Photography)

the couple would come to visit. “Living on the side of a mountain wasn’t what we saw for our future”. After the birth of their first child they started imagining what the business could be and saw the purchase as more of a possibility. “The rest is history” added Sarah. The couple decided to focus on distilled spirits and phased out the winery. Frank decided to use his knowledge of science and math to try his hand at distilling.

In March of this year, the couple was on vacation pre-COVID-19. One week later everything changed. Sara had packed some hand sanitizer and wet wipes for her young child. Since this is the distillery’s slow season, the couple began thinking about their options. “We do have alcohol” her husband noted and mentioned producing hand sanitizer. This was before liquor stores closed and prior to all of the hand sanitizer publicity. Within a few days they had ordered 8000 bottles and capsules. After reading state and federal regulations they learned that the product must be USDA/FDA certified. FDA has issued guidance for the temporary preparation of alcohol-based hand sanitizers by some companies and pharmacies during the public health emergency posed by COVID-19.

Photo by Sarah Kudlack

Using the World Health Organization (WHO)-recommended formulation they began producing sanitizer using out-of-pocket funds. The hand sanitizer is made with ethanol, glycerol, hydrogen peroxide and water resulting in a 99% kill rate for germs. Eventually they moved to a donation system in which larger organizations donated to cover production costs in return for sanitizer. This also allowed them to provide the product to some smaller organizations.

With liquor stores being closed at the beginning of the pandemic, sales increased but due to COVID-19 festivals have been cancelled impacting business. The distillery is currently offering curb-side pickup. The couple believes strongly in supporting local businesses which can be difficult to do in a rural area. Sarah noted that she is impressed by how people have “shown up in miraculous ways” during the pandemic. From sewing masks, delivering food to nurses and providing meal kits for children out-of-school she hopes that we do not forget the support shown and that lessons learned will carry on. “Small businesses are the foundation of our community and they deserve our support”, she said.

Photo by Sarah Kudlack

The couple has one additional large batch planned in this month but are waiting on capsules. The total number of bottles they produced is about 9,000 and at this point they plan on resuming production of distilled spirits. She noted that this will include shipping within PA and is working on distribution outside of PA. Some of the businesses that have benefited from the sanitizer include Walmart®, Smuckers®, UPMC and every post office within a thirty-mile radius. Additional beneficiaries include prison workers, nursing homes and hospice care. Sarah asked that we remember the efforts of small businesses and continue to support them. For more information please visit thier website at https://www.nomaddistilling.co/.

Considerations and Tips for Wine Bottling

By: Denise M. Gardner

It’s bottling season! Wineries are gearing up for the current growing season and another harvest. Now is the crunch time to get everything from last year’s vintage out of tank and barrel, and into bottle. Bottling is time intensive and tedious for a winery of any size, and it’s easy to leave the bottling line with contaminated wine bottles.

In fact, previous research has shown that even when sterile filtration steps are properly performed, over between 39-58% of the bottles leaving the bottling line end up with yeast in the bottle (Neradt 1982). Renouf et al. (2007) found that using sterile filtration (0.45 micron absolute filter or lower) was the only way to eliminate most microorganisms from the wine during bottling. However, in bottles that contained microbial populations upon bottling, Brettanomyces was able to bloom in the bottle after 6 months of storage, and increase 4-EP and 4-EG volatile phenol concentrations within 10 months post-bottling (Renouf et al. 2007). In fact, long term storage of red wines infected with Brettanomyces found this spoilage yeast became the dominate microbial population in the bottle, outcompeting most other microorganisms (Renouf et al. 2007). Yikes!

Bottling is one of the most important steps to retain wine quality at the winery. Therefore, this blog post will focus on a number of bottling considerations for wineries:

- Make pre-bottling additions before bottling day

Most product additions, including sulfur dioxide, potassium sorbate, gums, sugar, etc. require at least 24 hours of stabilization in wine before it can be sterile filtered and bottled. There are some exceptions, and some products may require longer stabilization time or need to be added during bottling, after filtration. You should rely on the advice of your product supplier when working with new additives. Additionally, some filter suppliers recommend making large sugar additions to wine at least a week before filtration.

If you are making the final sulfur dioxide addition the day before bottling, make sure you measure the concentration of free sulfur dioxide in the tank prior to bottling. Take multiple samples throughout the tank to ensure that the sulfur dioxide has penetrated all sections of the wine. If the sulfur dioxide is not high enough to reach the 0.85 ppm molecular level, it is best to alter additions and wait to bottle another day. For more information on sulfur dioxide additions at various wine pH’s, please click here.

- Cleaning…

Whether you have a manual bottling and capping system, or a high-tech bottling line, physically cleaning the bottling line is essential to maintaining proper hygiene in the winery. Bottling is one of the key areas where the quality of the product can greatly be degraded. Have brushes specific for the bottling line, and utilize detergents that break down wine debris or environmental dust.

Some bottling lines will require personnel to remove valves, hose lines, etc. to physically clean off debris or biofilms. Following cleaning operations, proper sanitation is essential to reduce microbial contamination through the bottling process.

*Note: The use of potassium sorbate will not inhibit contamination of your wine through bottling. Only proper sanitation techniques can reduce microbial populations and minimize risk of microbial spoilage in the bottle.

- …and Sanitation of the Bottling Line

As mentioned above, proper sanitation reduces microbial populations within food equipment and the surrounding environment, in order to reduce the risk of potential contamination within the packaged product – in this case, wine. While greatly underestimated, the surrounding environment is a potential contamination point in wineries, especially during bottling. Aseptic bottling operations are not necessary to maintain good hygiene, but it is often recommended that the bottling line be isolated within the winery to avoid large air movements while wine is packaged. This helps to avoid yeast, which are ubiquitous, contamination during the bottling process.

Floors, walls, and drains should be easily accessible and cleaned in the bottling area to help reduce environmental contamination. Routine environmental sanitation will also help reduce the risk of contamination.

Additional primary sources of contamination on the bottling line have previously been identified by Neradt (1982):

- Filler/Fill spouts

- Corker

- Bottle sanitizer

- Bottle mouth

- Filter

Proper sanitation of the bottling line first requires proper cleaning to remove all physical dirt and debris. Otherwise, the sanitation step is literally “cleaning dirt.”

Water chemistry, temperature, and contact time all affect the efficacy of sanitation. The use of soft water is often recommended for sanitation to avoid hard water residues that can harbor microbial populations.

The minimal temperature-time combination to sanitize equipment using hot water is 180°F (82°C) for at least 20 minutes. This temperature must be obtained at the coldest point in the bottling line. For bottling operations, this will be where water leaves the system. Butzke (2010) notes: “…that humans perceive water as painfully hot at temperatures just above 42°C (108°F).” Therefore, temperature readings should be taken with a calibrated, food-grade thermometer.

Individuals should take caution when working with scalding material or any chemical agent during the sanitation step. Always remember to ensure that employees have proper safety equipment and adequate ventilation.

Note that if you are using hot water, heat, or steam to sanitize the bottling line, you will need to bring the equipment back to the temperature of the wine to avoid cooking the first few gallons of wine that flow through the bottling line. Do not use tap water to change the temperature, as this will ruin the purpose of the sanitation step. Some wineries prefer to lose the first few gallons of wine, while others will follow a heat step with cold acidulated-sulfur dioxide mix.

Fill heads are an easy source of potential contamination. Periodically throughout bottling (i.e., every hour, or every time that breaks are taken), these can be sprayed or misted with 70% food-grade ethanol to ensure proper sanitation. Allow the ethanol to evaporate before proceeding. Wineries could also dip the ends in a properly made acidulated-sulfur dioxide mix. Do not wash off sanitized equipment with a towel or “clean” paper towel.

Always remember that the efficacy of cleaning and sanitation is dependent on the processor to complete this task correctly. Both cleaning and sanitation should take place immediately before bottling and immediately after bottling is completed. For more information on proper sanitation techniques, wineries can attend the Penn State Food Safety and Sanitation Short Course, which emphasizes key concepts related to sanitation processes. This course is also available in online content.

Additionally, the book, Winemaking Problems Solved, has an entire chapter designated to trouble shooting during bottling operations, and is recommended for any winery.

- Checking sterile filtration integrity

Filter integrity is an easy step that wineries can take to ensure their sterile filtration unit is working properly. Remember that sterile filtration requires the use of a 0.45 micron (or smaller) absolute filter cartridge. The Bubble Point Test is an integrity test that should be applied to a filter before and after bottling to ensure filter integrity.

- Bottle washing

While bottles are sterile when they are formed, many retain cardboard dust (“case dust”) in the bottles by the time they reach the bottling line in the winery, and this acts as a contamination point. Wineries should also be aware of tiny glass shards that may be retained within the bottle during glass manufacturing.

The best way to remove dust and debris in the bottle is by gas jetting: injecting a small stream of inert gas (e.g. nitrogen) prior to the bottle’s use.

As this is not a sanitation step, it is recommended that bottles also undergo a pre-rinse step with an approved no-rinse sanitizer. Many wineries utilize an acidulated-sulfur dioxide rinse or ozonated water.

- Inspecting filled bottles

Many wine microbiology text books recommend sampling one or two filled wine bottles every hour during bottling. There are several things that wineries can look for including using a microscope to scan for potential contamination, using membrane filtration to enumerate yeast and bacteria on a Petri Dish (pg. 236-238 in Wine Microbiology), or sending samples away to test for bottle sterility. This quality control step can help minimize worry post-bottling and provide ample feedback regarding bottle efficacy.

- Checking sulfur dioxide depletion

The use of sulfur dioxide is the last line of defense in terms of microbial stabilization while wine is in bottle. Many refermentation incidents are a result of too little free sulfur dioxide in the bottle.

During bottling, the wine will lose a little bit of the free sulfur dioxide concentration. Typically, this is around 10 ppm of free sulfur dioxide concentration, but it will vary from winery to winery, and bottling line to bottling line. Wineries should sample the sulfur dioxide concentration about 24 hours post bottling to evaluate the average loss of sulfur dioxide during the bottling process. Extra additions of sulfur dioxide can be made before bottling to compensate for the loss during the bottling process.

Resources & Literature Cited

Butzke, C. “How long do I need to disinfect my bottling line if my hot water is less than 82°C (180°F)?” in Winemaking Problems Solved

Microbiological Analysis of Grapes and Wine: Techniques and Concepts

Neradt, F. 1982. Sources of reinfections during cold-sterile bottling of wine. Am. J. Enol. Vitic. 33(3):140-144.

Renouf, V., M.-C. Perello, G. de Revel, and A. Lonvaud-Funel. 2007. Survival of wine microorganisms in the bottle during storage. Am. J. Enol. Vitic. 58(3):379-386.

Can you distill wine defects away?

By: Denise M. Gardner

By definition, wine defects are typically undesirable and unpleasant characteristics that occur in wine as a function of poor viticulture, winemaking, or storage techniques. The words “fault” and “defect” can be used interchangeably.

Perception of wine defects varies from individual to individual, which emphasizes the importance of sensory evaluation training amongst winemakers. If a winemaker is genetically blind to sensing a specific defect, and there is no secondary personnel available to “double check” the wine, wines may be bottled and sold to consumers faulted.

However, several wine defects can also be evaluated analytically throughout various stages of wine production. This emphasizes an importance of understanding analytical evaluation of wine and how it relates to wine quality.

While there is a lot of pride that goes into being a winemaker, wine defects happen. To everyone.

Sometimes these defects may reach concentrations that throw the wine out of balance or are beyond traditional remediation techniques. In these instances, a winemaker may turn to the use of distillation to treat wine defects with the hope of producing a distilled spirit that does not retain the perceived defect.

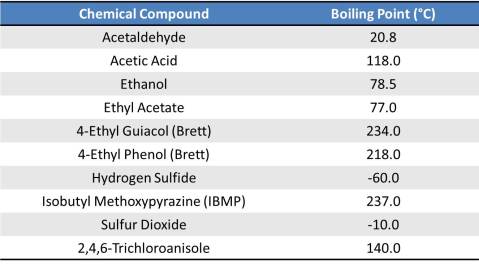

Pot Still from Willett Distillery

Distillation is used as a technique to concentrate ethanol from a fermented beverage. Typical spirits are produced from low-alcohol grain- or fruit-based fermented beverages. Pure ethanol, which has a lower boiling point (78.5°C) than water (100°C), vaporizes prior to water when heated. This physical property allows the separation of ethanol from water when it is properly heated. However, fruit-based fermented beverages are complex mixtures, and separation of other components, like odorous aroma compounds, may also be separated from the initial beverage.

The table below outlines the boiling points of common wine defects.

Based on this table, one may assume that many of these components can be easily separated from ethanol and water in the base product. In fact, older research literature has shown the reduction of many aldehyde-based compounds, some associated with wine oxidation, in commercial brandies produced in California (Guymon 1970). However, several compounds including hydrogen sulfide, “reduced” sulfur-containing compounds, sulfur dioxide, 2,4,6-trichloranisole (TCA, cork taint), methoxypyrazines, and some Brettanomyces-related aromas may be concentrated and retained in the final distillate.

Separation of aromatic compounds (volatiles) is not based on boiling point alone due to the fact that the base material, wine, is a complex mixture. Separation of volatile components will also be based on the relationship that compound has with ethanol or water (Léauté 1990). Many of these compounds like TCA, methoxypyrazines, or sulfur-containing compounds may be present in the base wine in such low concentrations that it may be challenging to effectively separate from the ethanol. However, some distillers point to the use of a copper still to help interact with sulfur containing compounds (such as hydrogen sulfide or thiols/mercaptans) to reduce these aromas in the distillate. One study found that dimethyl sulfide (DMS) was reduced when a copper still was used for distillation as opposed to a non-copper still (Fairia et al. 2003).

Concentration is also a factor for things like TCA or many methoxypyrazines, which are commonly present in wine in part per trillion (PPT) concentrations. In a study that evaluated distilled hard apple cider, the researchers identified several descriptors by use of olfactometry associated with making the distillate “defective:” sweat, vegetal, phenolic, old sponge, pyrazin, solvent, rot, mold, and herbaceous (Guichard et al. 2003). While the source of these sensory descriptors was not linked to any one aroma compound, some of these terms, like herbaceous and vegetal may be associated with methoxypyrazines or other aldehydic aroma compounds. Old sponge, rot, or mold may be associated with TCA and other spoilage volatiles. The study by Guichard et al., however, exemplifies how human perception of distillate dictates perceived quality.

Previous research associated with 4-ethyl guiacol (4EG) has shown retention of this aromatic compound in the distilled component called “the hearts.” Volatile components retained in the hearts have low boiling points and are typically soluble in alcohol (Léauté 1990). Therefore, retention of this odor compound may be altered based on where a distiller makes his or her cuts for distillate retention. In the case of batch distilling, it may be possible to further reduce these compounds by re-distilling a batch several times.

Solutions for Winemakers

The overarching message pertaining to distillation to remediate wine faults is that is not a fix-all solution to “cure” wine defects. In some cases, the winemaker may go from dealing with a faulted wine to receiving a faulted distilled spirit.

Many base wines used for distilled spirits are selected for flavor neutrality and nuance. Wines that contain faults are likely to contribute some additional nuance flavors that may not be expected in the final distilled spirit. Winemakers need to make sensory decisions to determine if a potential unexpected nuance flavor in the distilled spirit would be considered detrimental to the quality of their final product. If so, remediating the wine defect through alternative means may be necessary.

As with many issues pertaining to wine defects, the best way to ensure quality is to try to avoid the defect before it occurs in the wine. Receiving high quality raw material (i.e. grapes), using proper sanitation techniques, and managing oxygen exposure during wine processing can help winemakers avoid many wine defects.

More Information on Distilling Wine Defects

Previous Penn State Food Science undergraduate student, Erin Donnelly, published her review pertaining to the use of distillation to “cure” wine defects. This paper was later refined and published in the March-April 2015 Vineyard & Winery Management trade magazine, titled “Distillation of Faulted Wines.” Both articles are great references for further information on this topic.

Literature Cited

Guichard, H., S. Lemesle, J. Ledauphin, D. Barillier, and B. Picoche. 2003. Chemical and sensorial aroma characterization of freshly distilled calvados. 1. Evaluation of quality and defects on the basis of key odorants by olfactometry and sensory analysis. J. Agric. Food Chem. 51: 424-432.

Guymon, J.F. 1970. Composition of California commercial brandy distillates. Am. J. Enol. Vitic. 21(2): 61-69.

Faria, J.B., V. Ferreira, R. Lopez, and J. Cacho. 2003. The sensory characteristic defect of “cachaҫa” distilled in absence of copper. Alim. Nutr. 14(1): 1-7.

Léauté, R. 1990. Distillation in Alambic. Am. J. Enol. Vitic. 41(1): 90-103.

Hashtag Instagram

By: Abigail Miller

Images are one of the best ways of communicating with friends, family, and consumers. If you are not familiar with Instagram (instagram.com), it is a social media outlet that is a fun way to share your life or business through a series of pictures. It is easy to use: snap a photo with your smartphone or tablet, chose a filter to enhance your photo, and then post to Instagram, using the free app, for all your followers to view. What images should you post? Pictures of your employees working, products you are creating and selling, events that you hold at your winery, and everything else that shows what it would be like to visit your tasting room.

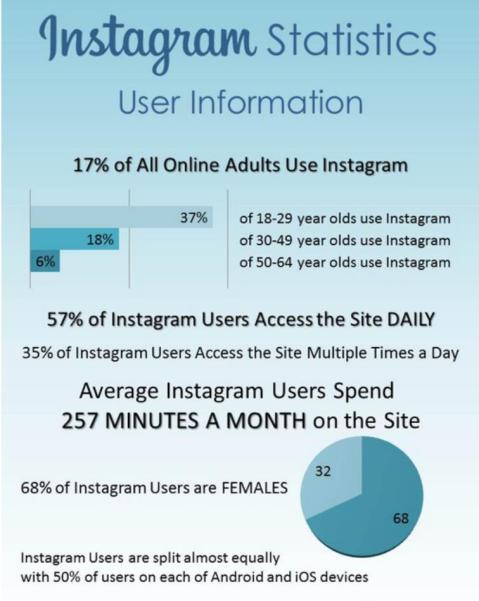

Now, you may not see Instagram as a beneficial tool for marketing your wines and winery, but this blog will help you understand the many advantages of using this tool.

With Instagram you can reach new audiences, in particular Younger Millennials and Generation Y (born between 1980s and 2000) (Noren, 2011), through visuals and short messages. Recently, a website edition of Instagram became available. This new addition allows businesses to create more of a “collage” of all the images you post, thus providing a better idea of what “goes on” at your tasting room.

You can also use Instagram to create engaging, “hands on” posts. For example, a great idea would be to create a photo contest through your Instagram account. Asking your followers to use a particular hashtag (#) (a word or an unspaced phrase prefixed with the hash character) for a contest by tagging (when you tag someone or tag a business, you create a link to their profile) their own pictures, when they post them to their own Instagram account, then select a winner and provide a prize. This is a perfect way to involve your consumers and followers while building excitement and interest in your business.

This is a snapshot directly from the Instagram app. If you simply search #lifedistilled, all of these images will appear and you will be able to see how many of Big Spring Spirits followers used their suggested hashtag when posting about the distillery.

This is an example of a hashtag that Big Spring Spirits, a distillery in Bellefonte, PA (www.instagram.com/bigspringspirits) used for their grand opening.

You can see in the upper left of the image there is text explaining how to use this hashtag when their customers post things to their social media pages. The hearts below the text indicate Big Spring Spirits followers ‘liking’ the image and idea of this post. The image below is showing the responses to the above post of the suggested hashtag to use for their grand opening.

In the upper right hand, you can see there are currently 70 images that have used the hashtag lifedistilled (#LIFEDISTILLED), all relating to Big Spring Spirits. Imagine the number of new followers and potential customers you could have by simply using a hashtag or contest to bring of a more hands on approach by involving your consumers.

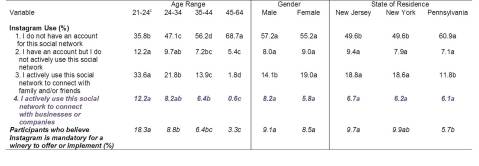

An Internet survey that was conducted 20-25 September 2013, focused on better understanding wine marketing strategies that would appeal to wine consumers in the Mid-Atlantic region (New Jersey, New York, and Pennsylvania). Survey participant use of Instagram was one of the social media outlets that we investigated in our research. Below, in Table 1, are results that indicate participant use of Instagram and the percentages (segmented by age range, gender and state of residence) who actively use Instagram to either connect with family and/or friends and/or to connect with businesses or companies.

Table 1. Participants’ responses (%) to questions asked during one Internet survey (20-25 September 2013) detailing the percentage participants use Instagram as a social media outlet and percentage that find it mandatory for a winery to implement.

Survey was administered 20-25 September 2013 to consumers residing in New Jersey, New York, and Pennsylvania.

z-Percentages with different letters within rows and demographic categories (age group, gender) represent Pearson’s Chi-Square and Games-Howell tests (SPSS, Chicago).

For the purpose of this post, we will focus specifically on the results for the percentage of participants who “actively use Instagram to connect with businesses or companies.” First, looking at the age range, participants who were between the ages of 21 and 24 were more likely to have used Instagram to connect with businesses (12.2%) from those between 35 and 64 years of age (6.4 and 0.6%, respectively); however, it is not statistically different from the second largest group of 24 to 34 year olds who use Instagram to connect with businesses (8.2%). Based on our results, it is clear that Millennials are most likely the main Instagram users who use the tool to connect with businesses, so it would be beneficial to use Instagram to specifically connect with this generation.

There were no statistical significant differences between genders or based on state of residence. Both males and females and participants from each of the three Mid-Atlantic states (New Jersey, New York, and Pennsylvania) were relatively equal in their use of Instagram to connect with companies.

Table 1 also portrays the percentage of participants who believe it is mandatory for a winery to have an Instagram account. Those aged 21 to 24 had the highest percentage of participants who responded that it was mandatory for wineries to have an Instagram account (18.3%), which was significantly greater than the percentages of participants in each of the other age ranges who felt this way. Again, there is no statistical difference between responses for this specific question based on gender. Pertaining to state of residence, more New Jersey participants (9.7%) responded that Instagram was mandatory for wineries to implement than Pennsylvania residents; however, neither differed (statistically) from the percentage of New York participants who responded this way.

Through our research we found that few of our survey participants, who were selected based on being a wine consumer, were using Instagram to connect with business or companies; however, general social-media research suggest that Younger Millenials (1980-2000s) are the primary users of Instagram. Based on the growing usage of Instagram and trends involving other social media outlets consumers use to connect with businesses, winery tasting rooms should at least investigate what social media tools (e.g. Facebook, Twitter, Pinterest, Instagram) their customers are using to connect with their business and others. It is possible that tasting room staff who do not use Instagram could be missing potential interaction with a portion of their target market.

So, why not learn more about Instagram? With so many beautiful pictures that can be taken at your tasting room, it is a simple way to share what goes on with customers through this outlet.

References

Noren, Laura. “Graphic Sociology.” The Society Pages. http://thesocietypages.org/graphicsociology/2011/10/04/who-is-the-millennial-generation-pew-research/. 4 October 2011.

Abigail Miller is a Master’s student at Penn State University, specializing in wine marketing. Her interests lie mainly within understanding the marketing and social media strategies appropriate for independent wineries, but she also enjoys learning about the production and wine making side of the business. Her hope is to one day become knowledgeable in all aspects of running a winery.

The project “Developing Wine Marketing Strategies for the Mid-Atlantic Region” (GRANT 11091317) is being funded by a USDA Federal-State Marketing Improvement Program grant, whose goal is “to assist in exploring new market opportunities for U.S. food and agricultural products and to encourage research and innovation aimed at improving the efficiency and performance of the marketing system.” For more information about the program, visit http://www.ams.usda.gov.

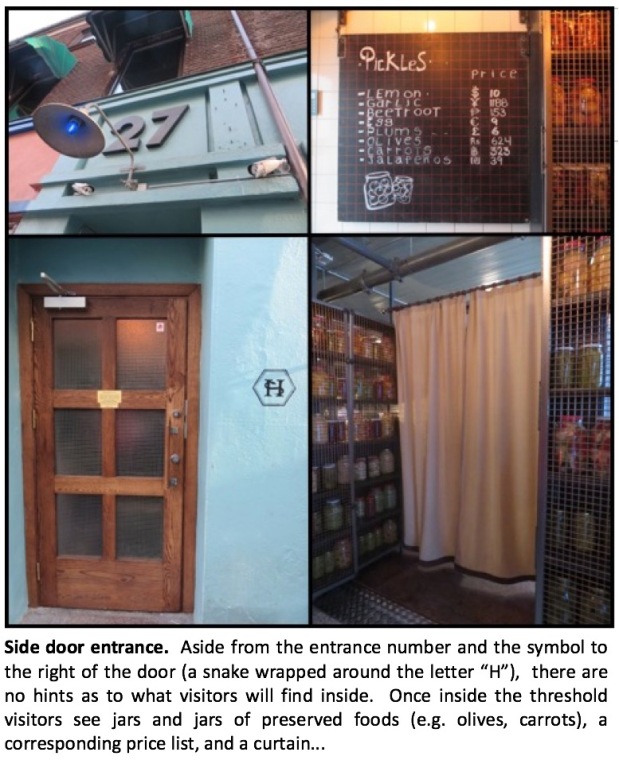

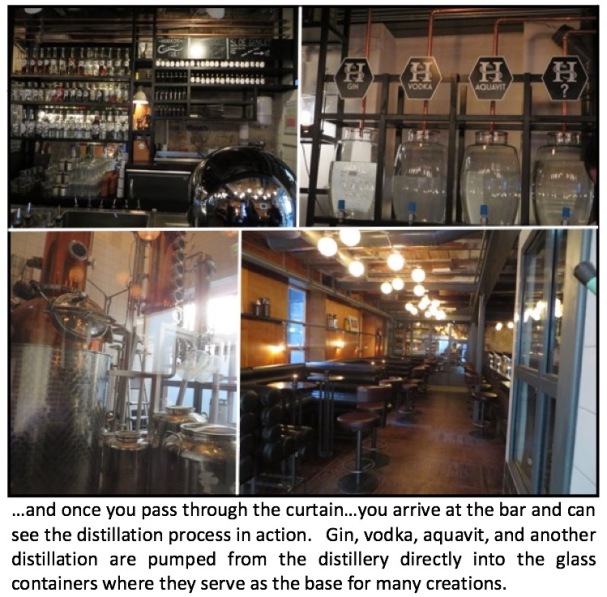

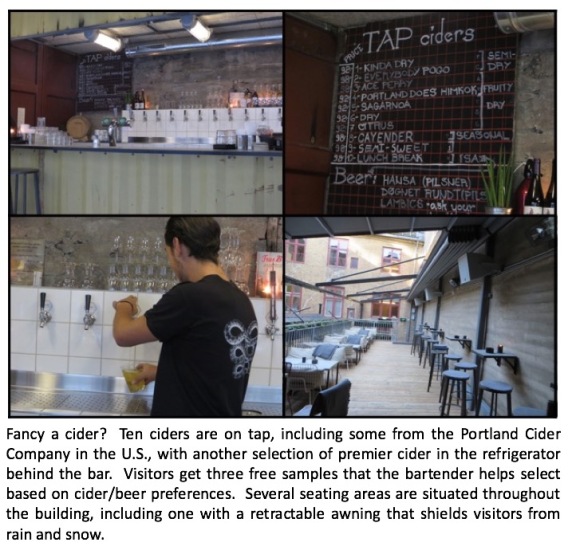

Defect and Flavor Training at Wigle Whiskey

By: Denise M. Gardner

Sensory defect and aroma/flavor training is one of the most valuable skills that anyone working in the alcohol beverage industry could learn. The awareness and ability to identify nuance flavors allows winemakers to produce detailed tasting notes, enhance marketing potential of their product, connect with consumer sensory perceptions, and better evaluate wines for quality. These facts are also true for distilled spirits and grain-based beverages.

As distillation (and brewing) are becoming popular additions to a winery’s business portfolio, it’s important to stress that these products also come with their own set of quality standards associated with their production. While fermentation is similar across all products (wine, beer, spirits), processing each should require the addition of an individual that specializes in production of that beverage. This allows for fewer production issues and more awareness of quality.

Wigle Whiskey, a distillery in Pittsburgh, PA invited me to their distillery to help train their staff members in nuance aromas/flavors and spirit defects. Luckily, many of the defects associated with spirits are also associated with wines (and beers). If you attended my talk at the 2014 EWE Conference, you may have heard me discuss the possibility of wine defects that can carry through the distillation process and into the final [spirit-based] product. Therefore, the quality of the base fermented product (wine, fruit wine, or beer) that goes into the still ultimately effects the final quality of the spirit.

What was accomplished during this training?

- Introduce the basic components associated with spirit sensory evaluation (appearance, aroma, taste)

- Emphasize common rules associated with sensory evaluation of spirits (e.g. expectorate, inhale delicately, do not attempt to taste more than 6 products in 1 sitting, etc.)

- Highlight those processing steps or additions that influence spirit aroma and flavor

- Introduce a series of defects associated with fermented beverages and discuss their potential sources through distillation

- Present defect, fermentation, and whiskey aging aromas to participants

- Evaluate commercial products against an in-house product in a blind tasting

This is an exercise that all wineries can implement into their tasting rooms and cellars. At this training session, we used pre-made aroma kits (by Le Nez du Vin and Wine Awakenings) to introduce employees to over 100 aromas associated with distilled spirits (and wines). Wineries can also used their Penn State Extension Enology Digital Defects Kits (flash drive) that were mailed to all Pennsylvania licensed wineries in May 2013. If you would like to receive a copy of this defects kit, please email me at dxg241@psu.edu. This kit was designed so that regular household products could be used to initiate the aroma identification of common wine defects.

By the end of the meeting, many commented on how regular trainings or tastings implemented at weekly staff meetings would help improve everyone’s sensory skills. Many winemakers, including Jim Law of Linden Vineyards, discuss how important it is for wineries to have regular tastings of various commercial products with staff to improve awareness of nuance aromas and flavors, understand quality wines, and refine employees’ palates (aka avoiding house or cellar palate).

Introducing Abigail (Abby) Miller

By: Kathy Kelley

One of the rewarding aspects of being a faculty member is mentoring young, energetic students and observing them develop interest in their research and helping them explore career paths. Currently, I have the pleasure of advising Abigail Miller, a Master’s student at Penn State, who is specializing in wine marketing research.

With a Bachelor’s degree in AgriBusiness and Telecommunications, Abigail is now using Internet surveys to investigate Mid-Atlantic consumers’ (those residing in Pennsylvania, New York and New Jersey) wine preference and purchasing behaviors, use of social media tools to connect with winery tasting rooms and brands, and attitudes towards wine produced in the three states. Over the next several months, blog postings describing some of the research will be published on this site. Funding for the project “Developing Wine Marketing Strategies for the Mid-Atlantic Region” (GRANT 11091317) was provided by a USDA Federal-State Marketing Improvement Program grant.

While Abigail’s main interests lie in understanding marketing and social media strategies appropriate for independent wineries, she also enjoys learning about the production and wine making side of the business. Her ultimate goal is to become knowledgeable in all areas of running a winery.

She’s not afraid to get her hands dirty. Here Abigail is making wine under the direction of Denise Gardner.

Before she began her graduate studies, Abigail interned at Seven Mountains Wine Cellars (Spring Mills, PA) during which she was able to be involved in marketing, production, bottling, and pouring samples in the tasting room. Currently she is the Social Media Coordinator at Big Spring Spirits (Bellefonte, PA) where she is providing guidance to the new distillery about social media outlets such as Facebook, Twitter, Foursquare, and Instagram.

As for her future career aspirations, which she’ll pursue after graduating in summer or fall 2015, she would like to work at a distributing company (Constellation, Treasury, etc.). Or, you might want to employ her as a marketing specialist at your winery and have her develop your social media presence and oversee your brand’s marketing strategy.

So, check back in a couple of weeks when we will begin publishing outcomes of the Abigail’s surveys.